Precision machining depends heavily on accuracy, repeatability, and secure workholding. Among the most trusted tools for achieving these standards is the 5C Collet Set, widely used in lathes, milling machines, and CNC applications. Known for its versatility and precision, the 5C system has become an industry benchmark for machinists working with small to medium-sized workpieces.

This article explores what makes a 5C collet set essential, how it benefits both lathe and milling operations, key features to consider when selecting one online, and common questions machinists ask before purchasing.

What Is a 5C Collet Set?

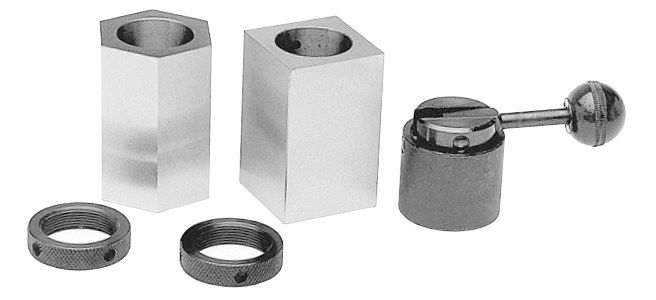

A 5C Collet Set consists of multiple collets designed to hold cylindrical, hexagonal, or square stock with high concentric accuracy. The “5C” designation refers to a standardized collet size and taper system that has been used in machining for decades. These collets fit into compatible spindles, collet chucks, or closers, making them adaptable across a wide range of machines.

Typically, a standard set includes collets in incremental sizes, allowing machinists to grip workpieces precisely without over-tightening or distortion.

Why 5C Collet Sets Are Ideal for Lathes

Lathes require stable and concentric workholding to produce accurate turned components. A 5C collet set excels in lathe operations due to:

Consistent Accuracy

5C collets provide excellent concentricity, often within a few microns. This minimizes runout and improves surface finish during turning operations.

Quick Setup

Compared to jaw chucks, collets allow faster loading and unloading of parts, improving efficiency for batch production or repetitive jobs.

Reduced Part Deformation

Because collets apply uniform pressure around the workpiece, they are less likely to deform delicate or thin-walled materials.

Benefits of Using a 5C Collet Set for Precision Milling

Although commonly associated with lathes, 5C collet sets are also widely used in milling applications. When paired with a 5C collet block or fixture, they offer:

Secure Workholding

A properly sized 5C collet holds material firmly during side cutting, drilling, or slotting operations.

Versatility

Collet blocks can be positioned vertically or horizontally, enabling complex milling setups without specialized fixtures.

Improved Repeatability

For precision milling tasks, repeatable positioning is critical. A quality 5C collet set ensures consistent results across multiple parts.

Key Features to Look for When Buying a 5C Collet Set Online

Selecting the best 5C collet set online requires careful evaluation of several technical factors:

1. Material and Heat Treatment

High-quality 5C collets are typically made from hardened alloy steel. Proper heat treatment improves durability, wear resistance, and long-term accuracy.

2. Size Range and Increments

A comprehensive set should include commonly used sizes, usually in 1/64″ or 1mm increments. This ensures optimal gripping without forcing stock into an oversized collet.

3. Accuracy and Tolerance

Look for collets manufactured to tight tolerances. Consistent bore size and concentricity are critical for precision machining.

4. Compatibility

Ensure the collets are compatible with your machine’s spindle, collet chuck, or closer system. Standard 5C collets are widely interchangeable, but it’s still important to verify specifications.

5. Finish and Build Quality

Smooth internal and external finishes reduce wear on both the collet and the workpiece, contributing to longer tool life and better results.

Common Applications of a 5C Collet Set

A 5C Collet Set is suitable for a wide range of machining tasks, including:

- Turning precision shafts and pins

- Milling small components and fixtures

- Drilling and tapping operations

- CNC production runs

- Toolroom and prototype work

Because of their adaptability, 5C collet sets are frequently used in automotive, aerospace, medical, and general manufacturing environments.

Maintenance Tips for Long-Term Accuracy

To maintain performance and accuracy, proper care of your 5C collet set is essential:

- Clean collets after each use to remove chips and debris

- Avoid overtightening, which can reduce accuracy over time

- Store collets in protective cases to prevent damage

- Periodically inspect for wear or deformation

Routine maintenance helps preserve concentricity and extends the life of the collet set.

FAQs About 5C Collet Sets

What size material can a 5C collet hold?

Standard 5C collets typically hold material up to 1-1/8 inches in diameter, depending on the specific collet design.

Can a 5C collet set be used on both manual and CNC machines?

Yes. 5C collet sets are compatible with both manual lathes and CNC machines when used with the appropriate collet chuck or closer.

Are 5C collets suitable for square or hex stock?

Yes. In addition to round collets, 5C systems include square and hex collets for holding non-round material securely.

How accurate are 5C collet sets?

High-quality 5C collets typically offer excellent concentricity, often within 0.0005 inches or better.

How many collets are usually included in a set?

This varies by manufacturer, but common sets include 10, 20, or 30 collets covering a wide size range.